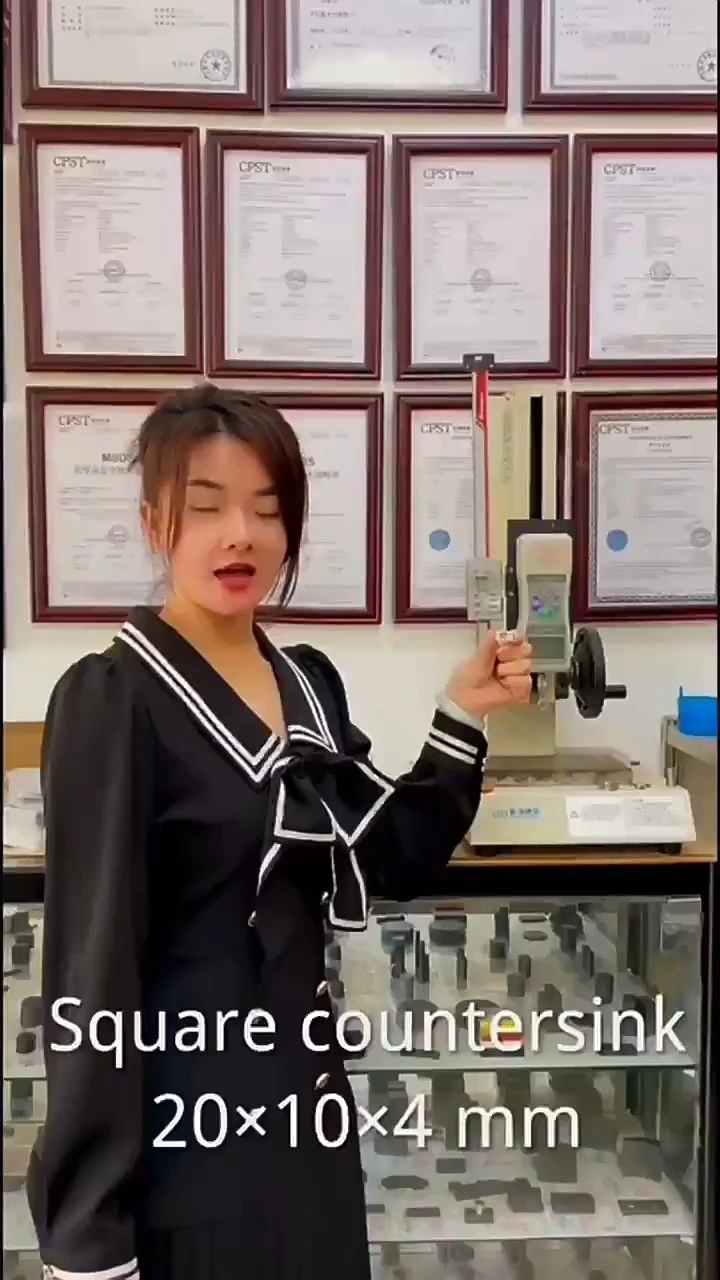

Rectangular N50 Neodymium Magnet Block with Countersunk Screw and Nickel Coating

Product Specifications

-

Material:

Our Neodymium magnets are made from high-quality sintered Neodymium Iron Boron (NdFeB), offering excellent magnetic properties and high stability. This material is ideal for applications that require strong and reliable magnetic fields. -

Size:

We offer a wide range of sizes for our Neodymium magnets, or custom sizes as per customer requests. Common sizes include diameter, thickness, and length, with precise size tolerances of ±0.05mm for diameter/thickness and ±0.1mm for width/length. Custom sizes can also be made to meet specific application needs. -

Shape:

Our Neodymium magnets come in various shapes, including disks, squares, rings, cylinders, sticks, cubes, countersunk designs, and irregular shapes. Custom shapes can be manufactured based on specific customer requirements, making these magnets suitable for a wide range of applications.

Performance Parameters

-

Magnetic Grades and Energy:

Our Neodymium magnets are available in different grades, including:-

N35, N38, N40, N42, N45, N48, N50, N52 with a maximum operating temperature of 80°C (176°F).

-

N35M, N38M, N40M, N42M, N45M, N50M, N52M with a maximum operating temperature of 100°C (212°F).

-

N35H, N38H, N40H, N42H, N45H, N50H, N52H with a maximum operating temperature of 120°C (248°F).

-

N35SH, N38SH, N40SH, N42SH, N45SH, N48SH, N50SH, N52SH with a maximum operating temperature of 150°C (302°F).

-

N33UH, N35UH, N38UH, N40UH, N42UH, N45UH with a maximum operating temperature of 180°C (356°F).

-

N30AH, N33AH, N35AH, N38AH with a maximum operating temperature of 220°C (428°F).

-

-

Coatings:

We offer several types of coatings to protect the magnets and extend their lifespan. Common coatings include:-

Ni-Cu-Ni (Nickel-Copper-Nickel) for corrosion resistance.

-

Custom coatings are available, such as Zn (Zinc), Ni-Cu-Ni, Gold, Silver, Copper, Epoxy, Chrome, and more, to meet the specific environmental or aesthetic requirements of different applications.

-

Magnetization Methods

Our Neodymium magnets can be customized to meet specific magnetization needs, with common magnetization methods including:

-

Thickness Magnetized: Magnetization is applied along the thickness of the magnet.

-

Axially Magnetized: Magnetization is aligned along the magnet’s axis.

-

Diametrally Magnetized: The magnetization is applied across the diameter of the magnet.

-

Multi-poles Magnetized: Multiple poles are created on the magnet's surface.

-

Radial Magnetized: The magnetization is radial, making it ideal for rotating applications.

Customized magnetization can be provided to meet specific customer requirements, ensuring the magnet performs optimally for its intended use.

Maximum Working Temperature

The maximum working temperature of Neodymium magnets varies depending on their grade:

-

N35 to N52 grades: Maximum operating temperature of 80°C (176°F).

-

N35M to N52M grades: Maximum operating temperature of 100°C (212°F).

-

N35H to N52H grades: Maximum operating temperature of 120°C (248°F).

-

N35SH to N52SH grades: Maximum operating temperature of 150°C (302°F).

-

N33UH to N45UH grades: Maximum operating temperature of 180°C (356°F).

-

N30AH to N38AH grades: Maximum operating temperature of 220°C (428°F).

Applications and Uses

-

Industrial Applications:

Neodymium magnets are widely used in industrial machinery, robotics, automation, and mechanical systems. Their high magnetic force ensures that they can hold heavy loads, secure components in place during operations, and provide reliable magnetic fields for sensors and actuators. These magnets are ideal for applications like magnetic couplings, holding mechanisms, and magnetic locking systems. -

DIY Projects and Crafts:

Thanks to their power and versatility, these magnets are perfect for DIY projects, crafts, and home improvements. The countersunk holes and compact designs make them easy to integrate into custom tools, devices, or magnetic mounts. They are often used for building magnetic closures for doors, cabinets, or creative art projects. -

Electronics and Sensors:

Neodymium magnets are critical for sensors and magnetic encoders, where strong but compact magnetic fields are needed. These magnets are found in a variety of applications, from position tracking to motion sensors. Their high magnetic strength ensures precise readings and reliable performance even in challenging environments. -

Holding and Mounting Solutions:

Whether for industrial fixtures or home installations, Neodymium magnets with countersunk holes offer a reliable and convenient way to secure items. The flush mounting feature ensures that items stay firmly in place, making them ideal for display mounts, signage, or machinery components that need to stay in position under constant pressure.

Advantages

-

High Magnetic Strength:

The N50-grade Neodymium magnets provide some of the highest magnetic strength available. They are perfect for heavy-duty applications where maximum holding force is required. Their high pull force ensures that components stay securely fixed, even under heavy loads. -

Durability and Longevity:

Coated with Nickel-Copper-Nickel, these magnets are highly resistant to corrosion and wear, ensuring long-term use even in harsh environments. They are ideal for use in outdoor machinery, automotive systems, and marine environments. -

Versatile Mounting Options:

The countersunk holes make installation easier and more versatile, allowing for secure mounting in a wide range of applications. Whether you're working with large mechanical systems or small-scale DIY projects, these magnets can be easily integrated into your designs. -

Compact and Space-Efficient:

Despite their powerful magnetic strength, these magnets are compact and space-efficient, making them perfect for use in tight spaces where larger magnets would be impractical. Their thin profile is ideal for applications where space is limited but strong magnetic force is still needed.

Value Proposition

Investing in these high-quality Neodymium magnets offers exceptional value for both industrial and consumer applications. They offer:

-

Reliability: With their high magnetic strength and durable coatings, these magnets provide reliable performance for a wide variety of applications.

-

Ease of Use: The countersunk holes and compact sizes make installation straightforward, saving time and effort.

-

Long-Term Savings: Due to their durability and corrosion resistance, these magnets require minimal maintenance, making them a cost-effective solution in the long run.

-

Versatility: Whether you need magnets for industrial, DIY, or electronics applications, these magnets provide unmatched versatility, ensuring you can use them in a variety of projects.

Conclusion

Whether you're a professional in need of powerful industrial-grade magnets or a hobbyist looking for reliable magnets for your next project, our Neodymium magnets with countersunk holes and nickel coating are the perfect choice. Their high magnetic strength, durable coating, and ease of installation make them an indispensable tool for a variety of applications. Upgrade your project or production with these high-performance magnets and enjoy the peace of mind that comes with their superior quality and reliability.

No. 73-75, Dalang Section, Guan Zhang Road, Dalang Town, Dongguan City, Guangdong Province, China